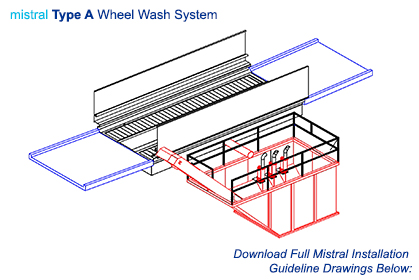

Wheel Washers – Type A

Description

The mistral A-System is a stationary wheel washer for removing light to heavy soiling from vehicle tyres. The system delivers 1 – 3 full tyre revolutions of cleaning power (depending on model) and has a maximum throughput of 60 trucks per hour.

Washing takes place as the vehicle slowly drives through the system and the wash cycle is automatically started via an optical sensor and variably controlled with a timer. The system includes a wash platform, side spray walls and a recycling tank for water treatment which is fitted with an integrated scraper conveyor for automatic sludge removal.

Function

A specially developed nozzle system, consisting of bottom nozzles in the wash platform and side nozzles in the spray walls, ensures for an efficient water spray profile for targeted cleaning of the tyre profiles plus outer and inner wheel surfaces. The direction of the side nozzles can be individually adjusted to optimise cleaning. The angled rumble grids that are integrated into the wash platform construction shake vehicles’ wheels and flex open tyre profiles to supplement the cleaning effect. Washed off sludge is directed into the system’s recycling tank which is located transversely underneath the wash platform. The waste sediment is automatically evacuated via the scraper conveyor and the water is circulated from the tank for reuse in the wash system. The water level in the tank is automatically regulated through a float valve. The use of a flocculent greatly increases and optimizes the sedimentation process and the flocculent is fed via an automatic dosing unit which is included in our standard scope of delivery.

Personnel

The A System has a totally automatic operation. Operators need only to periodically check and control the nozzles and conveyor system plus ensure a sufficient water supply to the recycling tank. A representative of mistral will instruct the customers’ personnel on routine checks and cleaning of the system during commissioning and handover.

Preparation for installation

The customer is responsible for preparing a tank pit with a concrete or compacted gravel base; suitable foundations for the wash platform plus water and electrical power supplies in accordance with the mistral installation guideline drawing.

Guarantee

The complete System carries a standard manufacturer’s guarantee of 24 months effective from the date of installation. mistral guarantees a permanent supply of spare parts and an established after-sales service.

Available Optional Accessories:

|

|

Sludge Container

“Flipper” Boot Cleaner

Heated Tanks

Insulated Equipment Container

We also design and manufacture bespoke and extra-large systems for dumpers, wheel-loaders, military tanks and other large vehicles.

| Technical Specifications | mistral 400A | mistral 700A | mistral 1000A |

|---|---|---|---|

| Maximum trucks per hour: | 40 * | 50 * | 60 * |

| Drive-through width: | 2.75 m | 2.75 m | 2.75 m |

| Total width (incl. tank): | 6.40 m | 6.40 m | 6.40 m |

| Total drive-through length: | 4.00 m (1 x tyre revolution) | 6.70 m (2 x tyre revolutions) | 9.40 m (3 x tyre revolutions) |

| Total installed length: | 4.00 m | 6.70 m | 9.40 m |

| In-ground depth: | 2.70 m | 2.70 m | 2.70 m |

| Standard side wall height: | 1.50 m | 1.50 m | 1.50 m |

| Total system weight: | 5.1 t | 6.6 t | 10.7 t |

| Electrical input: | 11.5 kW | 17.0 kW | 22.5 kW |

| Tank useful volume: | 9 m³ | 12 m³ | 17 m³ |

| Water use per wash cycle: | Ca. 25 litres | Ca. 25 litres | Ca. 30 litres |

| Number of wash pumps: | 2 | 3 | 4 |

| Maximum pump output: | 3600 l/min. | 5400 l/min. | 7200 l/min. |

| No. of Wash Platform Nozzles: | 88 | 136 | 176 |

| No. of Side Nozzles: | 16 | 24 | 32 |

| Download mistral Installation Guideline Drawings | 400A |

700A |

1000A |